Listening to our customers

We provide our customers with outstanding expertise and advice thanks to our wealth of experience. Our design office will keep you informed, thus optimizing the production of your components.

Polymer materials

Selecting the right material is vital to the success of your project. As there are lots of different materials with characteristics suited to specific requirements, we will help you to select the one that best meets your needs.

We also provide you with the option of developing your own materials. We inject around 20 different types of high-performance polymer which comply with the RoHS and REACH directives. The main ones are: (Non-exhaustive list)

PEEK

Polyéther éther cétone

PPS

Polysulfure de phénylène

PPSU

Polyphénylsulfone

PVDF

Polyfluorure de vinylidène

PAI

Polyamide imide

TPE

Polyester élastomère

PC

Polycarbonate

PMMA

Polyméthacrylate de méthyle

Deploying our expertise to achieve your goals

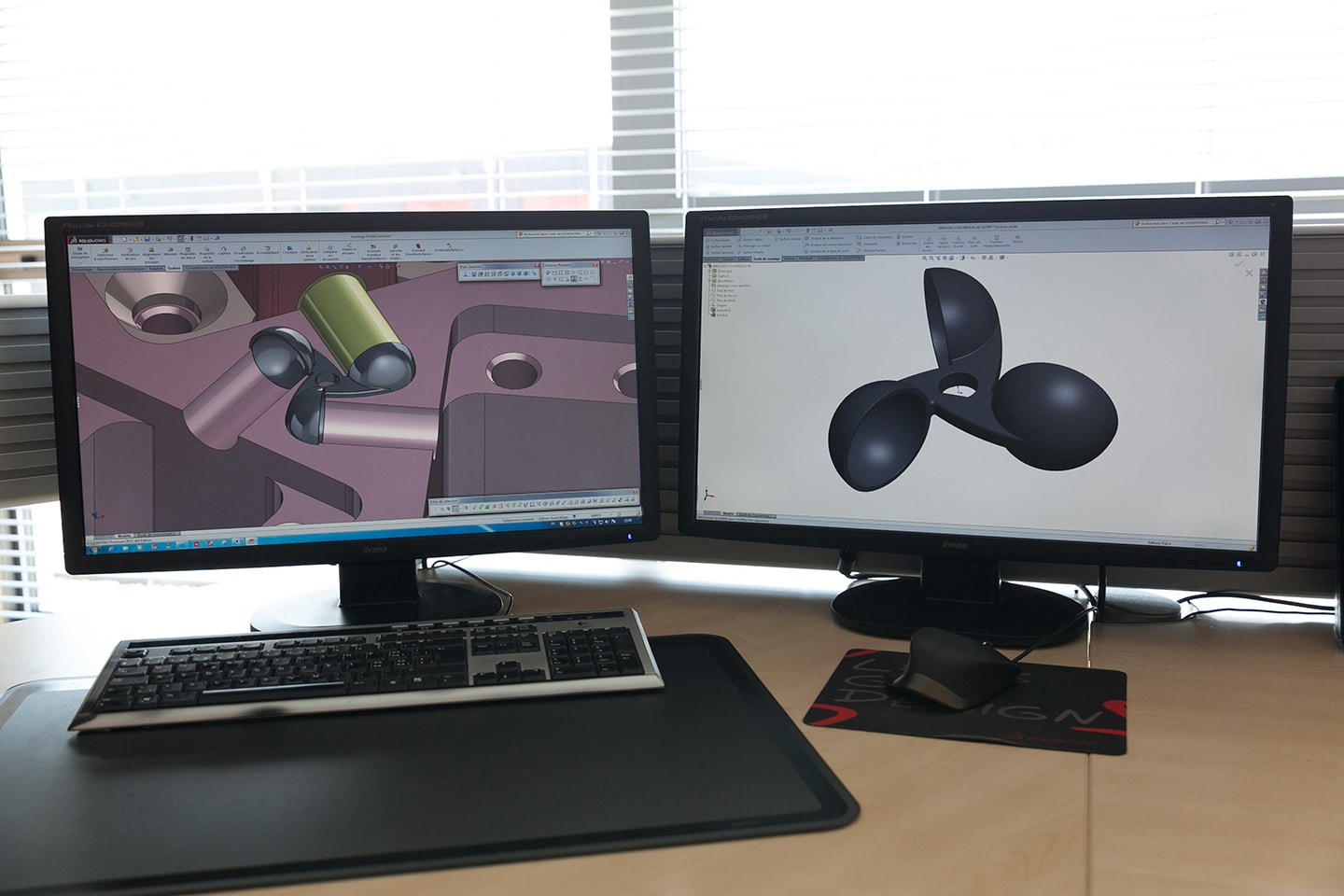

Modification of plans

Your plans will most likely require some modification to comply with the established process. Thanks to its confident command of SolidWorks, our team will ensure your projects are dealt with to the highest standards of quality and professionalism. We carry out a rheological study – a simulation of the injection process – enabling customers to visualize and understand the procedure the material undergoes in the moulds and the validation process.